On the production floor, every minute counts. In an environment where precision and time are critical, even a small misunderstanding can disrupt the entire schedule. Paweł’s story from the production line illustrates how simple changes can revolutionize daily work.

Working in a rush

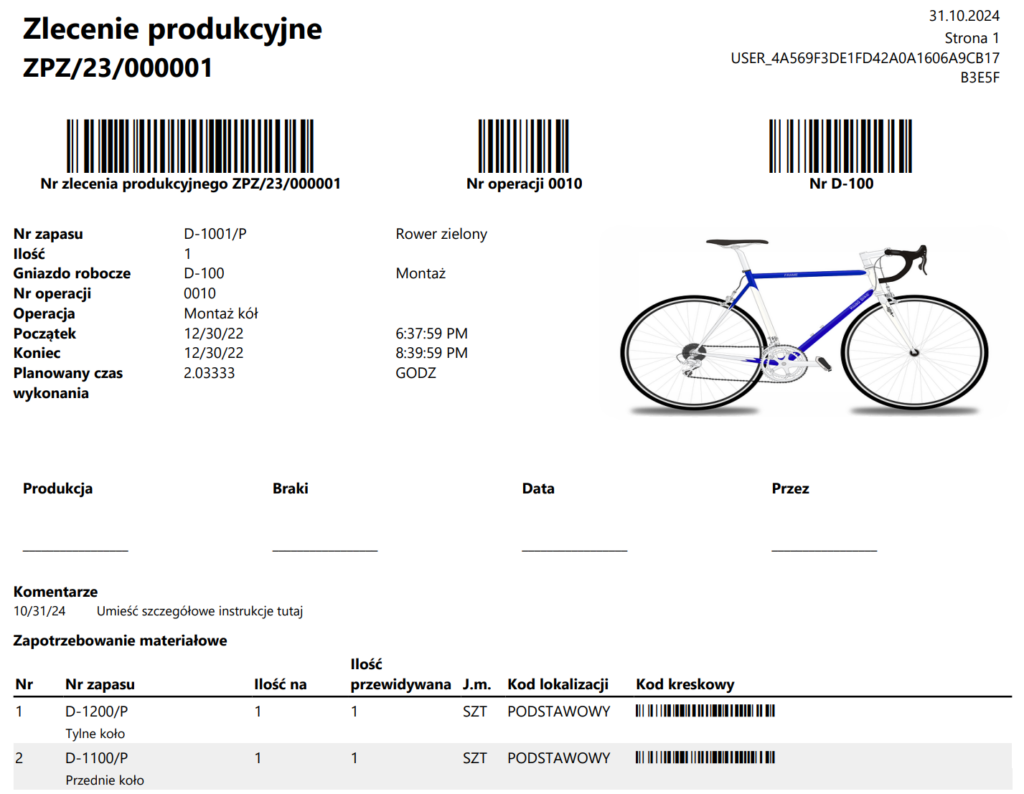

For several months, Paweł had been working on the production line at a large company manufacturing automotive parts. His day began by picking up production orders. While these documents contained a variety of information, they were not always sufficient. The names of the items being produced often sounded similar, there were no clear instructions, and the production order cards lacked images, sometimes leading to mistakes.

One day, Paweł encountered the kind of order he had long dreaded—a critical order for a major client, involving numerous items with similar names. Paweł quietly thought about how much easier it would be if every order included an image of the item along with clear instructions on what needed to be done.

The day a wrong component was installed in production became a turning point. In the rush, the incorrect part was added to the wrong place due to a lack of instructions. This nearly resulted in an accident, delayed production, and put the on-time delivery of the client’s order at risk. Managers had to act immediately to address the issue and began considering improvements.

Introducing Core Printouts – Manufacturing

With the introduction of this solution, the factory where Paweł worked gained new capabilities. From now on, every production order card featured an image of the item being produced and brief descriptions in the form of comments clearly stating what needed to be done. Paweł could now instantly see the final product and receive instructions if something required special attention.

Thanks to Core Printouts – Manufacturing, you can combine the precision of modern technology with the simplicity of paper printouts, enabling employees to leverage their expertise without the risk of errors.

Want to learn how our solution can enhance your production processes? Contact us and discover the full potential of this advanced tool!